The Megapro Ratcheting screwdriver is one of our crowning achievements as a tool manufacturer. It’s one of the best multi-bit ratcheting drivers on the market and it has backed that claim up with great reviews and product tests. But as anyone who’s ever been at the top of their game can confirm, you have to put in the work to stay there, and the work Megapro has done to stay at the top can best be described by one word: Refinement.

What makes the Megapro Ratcheting Screwdriver stand out from other brands?

Scott: It’s difficult on the surface to point out what stands out about our Ratcheting Screwdriver because there’s so many other companies that make a Ratcheting screwdriver, ranging from cheaply made to expensive, high-end brands (none of which we’ll mention here. This is a Megapro Blog after all).

Something we can say about our Ratcheting driver is that we have gone through a lot of work and effort to make it as reliable and strong as possible, and we’re still on the lookout for ways to improve it.

What in-use features of the Megapro Ratcheting driver show the quality of the tool?

Scott: A good indicator of our Ratchet quality is actually the sound it makes in use. Hermann (the inventor of Megapro screwdrivers) is a musician and so sound matters a lot to him and it says a lot about the consistency of our driver function. How does it sound when it’s in use? Is the sound the same in both directions? The sound gives us feedback and tells us that it’s been machined and assembled properly.

In addition, our ratcheting driver is easy to use, compact and very strong. You can grasp and torque the handle as hard as you want but you ARE NOT going to break it. Your hands will slip, and you’ll struggle to turn the driver hard enough before you even come anywhere close to breaking the ratchet mechanism.

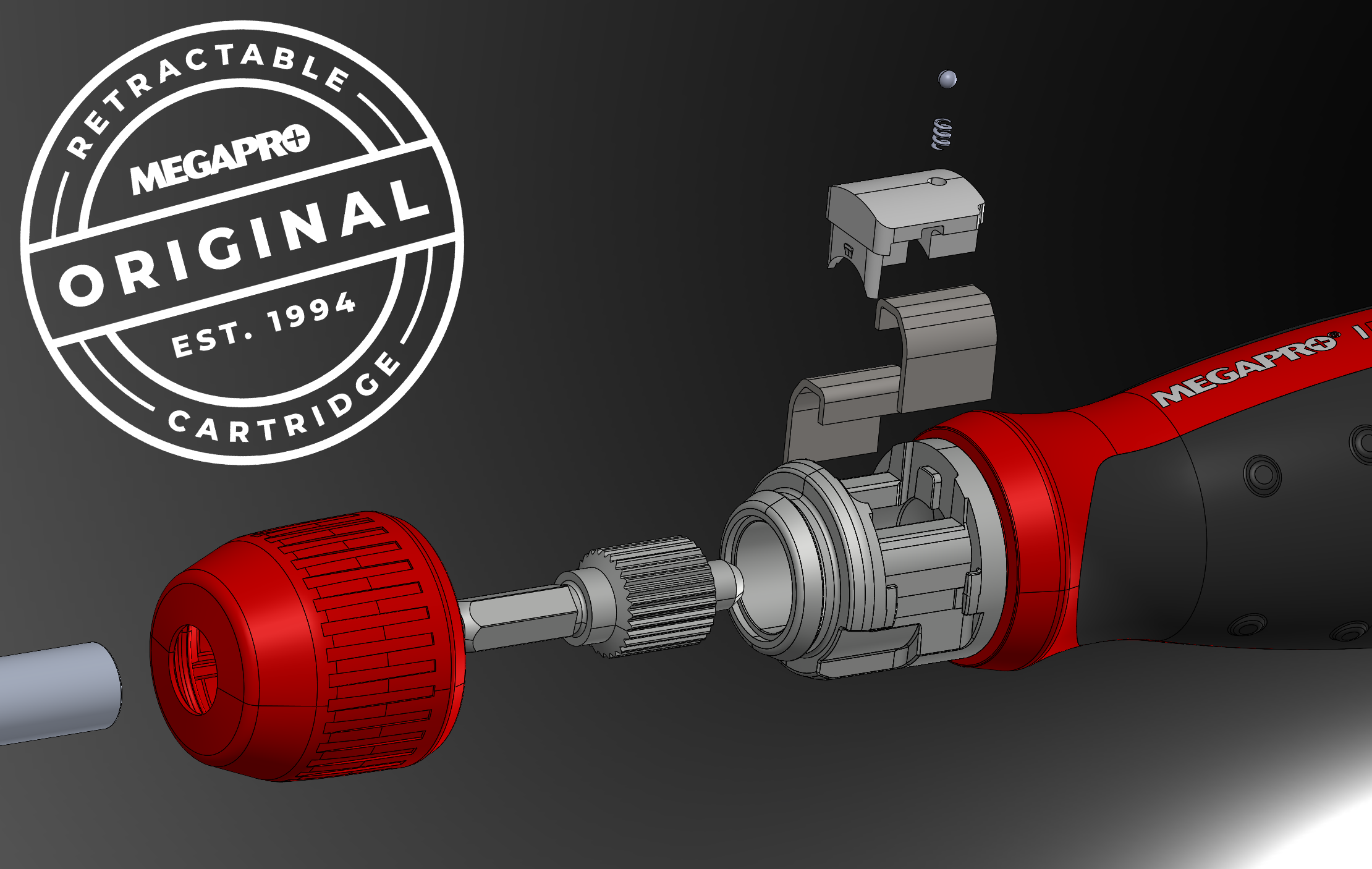

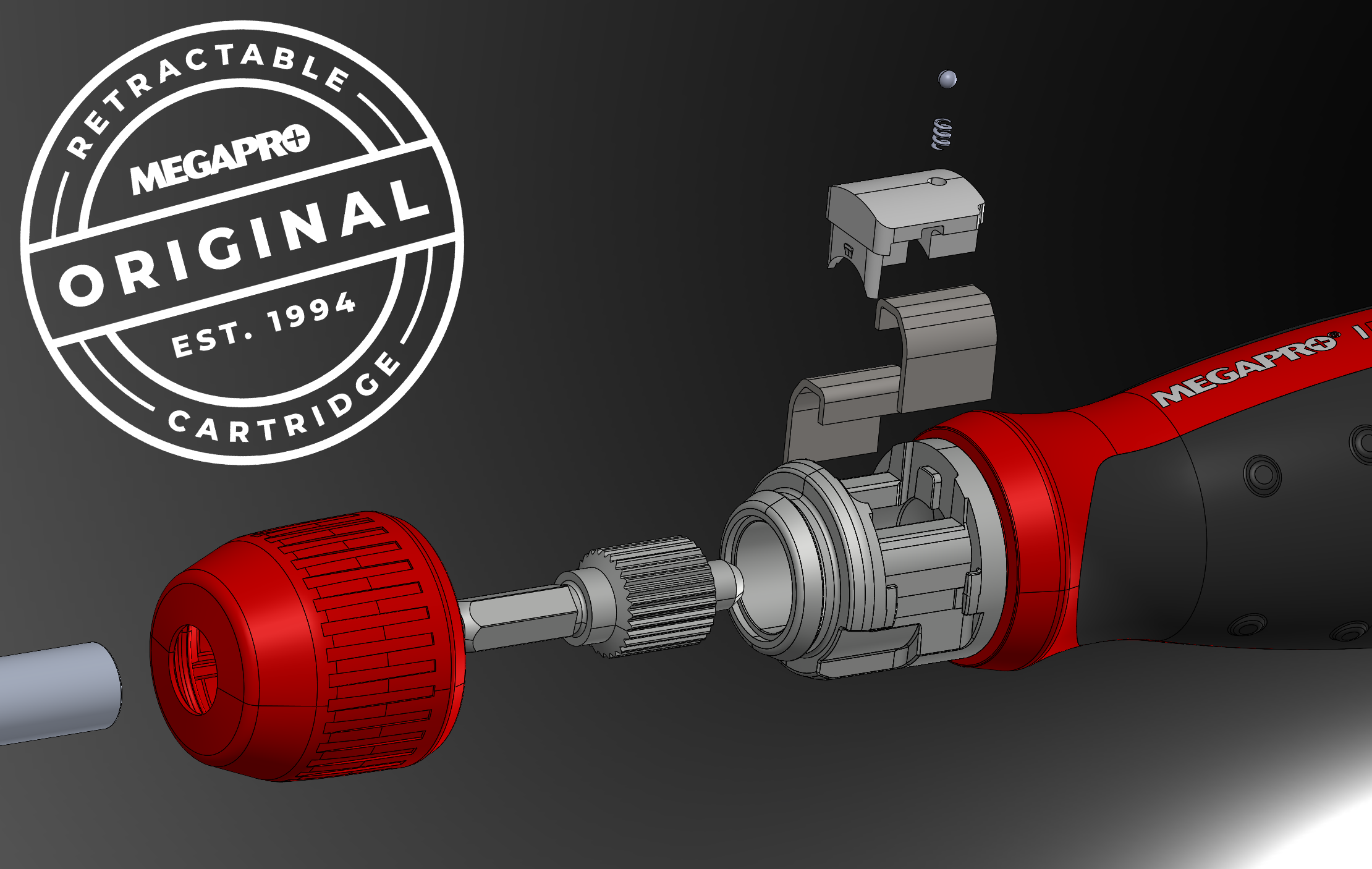

What benefit does using the Zinc Alloy in the Ratchet Mechanism produce?

Scott: Zinc traditionally doesn’t have a reputation as a strong metal to use for production, but when I started here, I learned that the biggest benefit of using Zinc casting is that the tolerances are very precise. This really matters when you have something that must fit in a small ratchet housing. If something is off even a few thousandths of an inch, that can really impact the way the driver operates. So, the better the precision and spacing of the components the more likely the ratchet will consistently work the way it’s meant to work with minimal movements.

How do all these mechanical functions and design decisions benefit the end user?

Scott: The biggest benefit of putting all this effort into manufacturing the screwdriver is that you know it works in all situations. If you’re out in the open and you have the clearance to turn the screwdriver properly, sure the ratcheting mechanism helps you get the job done faster but that’s not really where it shines.

Say you’re working under a rust bucket ‘73 Camaro and you’re reaching up under the engine to get at a rusted screw that you can’t see. You don’t have the room to properly use a regular screwdriver, so you need a ratcheting driver. If you can’t hear or feel the ratchet working because you’ve bought a cheap ratcheting driver you won’t be sure it even turned the screw. Being sure you got the job done because you went with a high-quality ratcheting driver that works is critical in a lot of situations.

And there you have it folks! We hope this has provided you with a bit more insight into how our Ratcheting Driver’s quality and function has led it to be the popular product it is today. There’s something to be said about a driver’s reputation when some big companies approach us to help them manufacture their own Ratcheting driver ;)

To keep up to date on all of our products and to see some more interesting Megapro insights, sign up for our online newsletter here.